For detailed cases, please contact the consultant.

400-969-2866

2024-07-18 02:15:05 Source: Champu Consulting Visits:0

Analysis on the Development Environment of 1. Textile Machinery Manufacturing Industry

(I) political and legal environment

In 2022, China's textile industry is facing an extremely severe external development environment, weak market demand, high raw material costs, more complex trade environment and other risk factors on the textile industry caused a greater impact, economic operation pressure significantly increased.2023The year is the first year to fully implement the spirit of the 20th National Congress of the Communist Party of China, and it is also the year for the textile industry to move towards the new goal of building a modern industrial system in an all-round way. The development situation remains complex and grim. The textile industry still needs to work hard to consolidate the foundation of economic recovery, continuously release the potential of high-quality development, and make new contributions to the completion of the macro-control objectives of stable growth and stable employment and stable prices and the high-quality opening of the new situation of building a modern textile industry system.

To this end, the state and industry associations have issued a series of policies, regulations and development plans to guide and support the transformation, upgrading and innovative development of the textile machinery manufacturing industry. For example:

Guiding Opinions on Promoting the High Quality Development of China's Equipment Manufacturing Industry2It puts forward the goals and measures to accelerate the digitalization, networking, and intelligent transformation and upgrading of the equipment manufacturing industry, enhance the core competitiveness and innovation capabilities of the equipment manufacturing industry, and build a powerful equipment manufacturing country with global influence.

Guiding Opinions on Promoting the High Quality Development of China's Textile and Garment Industry1The tasks and requirements of accelerating the optimization of textile and garment industry structure, brand promotion, green development, innovation driven, open cooperation and so on are put forward.

Guiding Opinions on Promoting the High Quality Development of China's Textile Machinery Industry3The goals and measures of accelerating the intelligent, green, service-oriented and international textile machinery industry are put forward.

These policies, regulations and development plans provide a clear development direction and policy support for the textile machinery manufacturing industry, which is conducive to stimulating the innovation and market vitality of the industry and promoting the high-quality development of the industry.

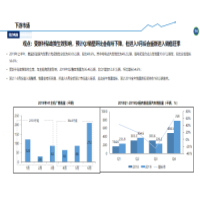

(II) economic environment

According to data from the Champ Consulting Group,2022In 2010, the market size of the global textile machinery manufacturing industry reached about1000Billion US dollars, up about5%. Among them, the Asia-Pacific region is the world's largest textile machinery manufacturing market, accounting for about40%It mainly benefits from the rapid development of the textile and garment industry in China, India, Bangladesh and other countries and the large demand for textile machinery. Europe is the world's largest textile machinery manufacturing export region, accounting for about the share of global exports.50%It mainly relies on the technological advantages and brand influence of Germany, Italy, Switzerland and other countries to provide high-end, efficient and high-quality textile machinery products around the world. North America is the innovation leading region of the global textile machinery manufacturing industry, mainly represented by the United States, and constantly introducing new technologies, new products and new models to provide new impetus for the development of the industry.

For the whole of 2023, the global textile machinery manufacturing market is expected to reach approximately1050Billion US dollars, up about5%. With the global economic recovery and the effect of epidemic prevention and control, the global textile and apparel market demand will gradually recover and grow, thus driving the demand for textile machinery. At the same time, with the continuous development and application of digital, intelligent, green and other technologies, the textile machinery manufacturing industry will usher in a new round of technological innovation and product upgrading, bringing new opportunities for the development of the industry.

According to data from the Champ Consulting Group,2022The total import and export volume of China's textile machinery manufacturing industry reached88.95Billion US dollars, up about10%. Among them, the export amount is55.4Billion US dollars, up about15%; Imports are33.55Billion US dollars, up about3%. China's textile machinery manufacturing industry to achieve a trade surplus21.85Billion US dollars, up about35%. These data show that China's textile machinery manufacturing industry has strong competitiveness and influence in the international market, and also reflects the continuous improvement and improvement of China's textile machinery manufacturing industry in terms of technical level and product quality.

In 2023, the total import and export volume of China's textile machinery manufacturing industry is expected to reach about95Billion US dollars, up about7%. Among them, the export value will reach about60Billion US dollars, up about8%Imports will reach about35Billion US dollars, up about4%. China's textile machinery manufacturing industry will continue to maintain a trade surplus25Billions of dollars or so. These data indicate that China's textile machinery manufacturing industry will maintain a stable development trend in the domestic and foreign markets, and will also face more intense competition and higher requirements.

(III) social environment

The development of the textile machinery manufacturing industry is affected by the social environment, which is mainly reflected in the following aspects:

consumer demand. With the improvement of people's living standards and changes in consumer attitudes, consumers' demand for textiles is becoming more and more diversified, personalized and high quality, which requires the textile machinery manufacturing industry to provide more flexible, intelligent, efficient and environmentally friendly textile machinery products to meet the needs of different consumers.

Environmental protection. Textile machinery manufacturing industry is a high energy consumption and high pollution industry, which has a certain negative impact on the environment. With the enhancement of social awareness of environmental protection and the improvement of environmental regulations, the textile machinery manufacturing industry must strengthen energy conservation, emission reduction, recycling, waste disposal and other aspects of the work to reduce the impact on the environment and risk.

Talent training. Textile machinery manufacturing industry is a technology-intensive, innovation-driven industry, which requires a large number of professional and technical personnel and management personnel. With the increase of social investment in education and the development of the talent market, the textile machinery manufacturing industry needs to strengthen cooperation with universities and scientific research institutions, cultivate and introduce more talents with innovative spirit and practical ability, so as to enhance the core competitiveness of the industry.

The development of the textile machinery manufacturing industry has also had an impact on the social environment, mainly in the following aspects:

Economic contribution. Textile machinery manufacturing industry is an important basic industry to support the development of China's textile and garment industry, providing a large number of high-quality products and services for domestic and foreign markets, creating huge economic value and social benefits.2022China's textile machinery manufacturing industry achieved a trade surplus in21.85billion dollars, contributing to the country's foreign exchange reserves.

Employment income generation. Textile machinery manufacturing industry is a labor-intensive industry, which provides a large number of jobs and income sources for the society.2022The number of employees of enterprises above the scale of China's textile machinery manufacturing industry reached about60It has played an important role in social stability and the improvement of people's livelihood.

technological progress. The textile machinery manufacturing industry is a technological innovation industry, which continuously introduces new technologies, new products and new models, providing new impetus for the development of the industry. At the same time, the textile machinery manufacturing industry has also promoted technological progress and industrial upgrading in related industries and fields, such as electronic information, new materials, and new energy.

Market Scale Analysis of 2. Textile Machinery Manufacturing Industry

Market Scale Analysis of Global Textile Machinery Manufacturing Industry in (I)

According to data from the Champ Consulting Group,2022In 2010, the market size of the global textile machinery manufacturing industry reached about1000Billion US dollars, up about5%. Among them, the Asia-Pacific region is the world's largest textile machinery manufacturing market, accounting for about40%It mainly benefits from the rapid development of the textile and garment industry in China, India, Bangladesh and other countries and the large demand for textile machinery. Europe is the world's largest textile machinery manufacturing export region, accounting for about the share of global exports.50%It mainly relies on the technological advantages and brand influence of Germany, Italy, Switzerland and other countries to provide high-end, efficient and high-quality textile machinery products around the world. North America is the innovation leading region of the global textile machinery manufacturing industry, mainly represented by the United States, and constantly introducing new technologies, new products and new models to provide new impetus for the development of the industry.

For the whole of 2023, the global textile machinery manufacturing market is expected to reach approximately1050Billion US dollars, up about5%. With the global economic recovery and the effect of epidemic prevention and control, the global textile and apparel market demand will gradually recover and grow, thus driving the demand for textile machinery. At the same time, with the continuous development and application of digital, intelligent, green and other technologies, the textile machinery manufacturing industry will usher in a new round of technological innovation and product upgrading, bringing new opportunities for the development of the industry.

Market Scale Analysis of China Textile Machinery Manufacturing Industry in (II)

According to data from the Champ Consulting Group,2022The total import and export volume of China's textile machinery manufacturing industry reached88.95Billion US dollars, up about10%. Among them, the export amount is55.4Billion US dollars, up about15%; Imports are33.55Billion US dollars, up about3%. China's textile machinery manufacturing industry to achieve a trade surplus21.85Billion US dollars, up about35%. These data show that China's textile machinery manufacturing industry has strong competitiveness and influence in the international market, and also reflects the continuous improvement and improvement of China's textile machinery manufacturing industry in terms of technical level and product quality.

In 2023, the total import and export volume of China's textile machinery manufacturing industry is expected to reach about95Billion US dollars, up about7%. Among them, the export value will reach about60Billion US dollars, up about8%Imports will reach about35Billion US dollars, up about4%. China's textile machinery manufacturing industry will continue to maintain a trade surplus25Billions of dollars or so. These data indicate that China's textile machinery manufacturing industry will maintain a stable development trend in the domestic and foreign markets, and will also face more intense competition and higher requirements.

Analysis on Technological Progress of 3. Textile Machinery Manufacturing Industry

Analysis of Technological Progress of Global Textile Machinery Manufacturing Industry in (I)

Textile machinery manufacturing industry is a technology-intensive, innovation-driven industry, the level of technology directly affects the performance, quality, efficiency and environmental protection of products, which determines the competitiveness and development prospects of enterprises and industries. With the changes in the global textile and apparel market and the upgrading of consumer demand, the textile machinery manufacturing industry is also facing challenges such as continuously improving product added value, reducing production costs, improving energy efficiency, and reducing environmental pollution. This requires textile machinery The manufacturing industry continues to carry out technological innovation and product improvement to meet market demand and social development.

The technological progress of the global textile machinery manufacturing industry is mainly reflected in the following aspects:

Digitization. Digitalization refers to the use of digital technology to optimize and integrate the design, production, management and service of textile machinery to realize the integration of information, networking, intelligence and service. Digital technology can improve the accuracy, flexibility, efficiency and reliability of textile machinery, while also reducing production costs, saving resources and protecting the environment. Digital technology includes digital design, digital simulation, digital control, digital detection, digital management and so on.

Intelligent. Intelligence refers to the use of artificial intelligence, Internet of Things, big data, cloud computing and other technologies for intelligent perception, intelligent control, intelligent optimization and intelligent decision-making of textile machinery to achieve automation, intelligence and advanced forms of human-machine collaboration. Intelligent technology can improve the adaptability, learning, innovation and interactivity of textile machinery, and can also improve product quality, production efficiency and operation and maintenance effect. Intelligent technology includes intelligent sensing, intelligent driving, intelligent diagnosis, intelligent adjustment and so on.

Greening. Greening refers to the use of clean energy, new materials, new processes and other technologies to transform and innovate textile machinery in terms of energy saving, emission reduction, recycling, and waste treatment to achieve a low-carbon, environmentally friendly and sustainable development model. Green technology can reduce the energy consumption, emissions and pollution of textile machinery, but also can improve resource utilization and social responsibility. Green technologies include electrification, lightweight, oil-free, and biodegradation.

Analysis on Technological Progress of China's Textile Machinery Manufacturing Industry in (II)

After years of development, China's textile machinery manufacturing industry has formed a complete industrial chain and rich product varieties, with strong production capacity and market competitiveness. However, compared with the international advanced level, there is still a certain gap in China's textile machinery manufacturing industry, mainly in the lack of independent innovation ability of high-end products, the technical level and stability of key components is not enough, digital, intelligent, green and other aspects of the application is not extensive enough.

In order to narrow the gap with the international advanced level and enhance the core competitiveness and innovation ability of China's textile machinery manufacturing industry, China's textile machinery manufacturing industry has increased investment in technology research and development and innovation, strengthened cooperation with universities and scientific research institutions, and promoted the development and application of digital, intelligent and green technologies, and achieved some breakthrough results. For example:

Digitization. China's textile machinery manufacturing industry actively promotes the application of digital design, digital simulation, digital control and other technologies, realizing the digitization of the whole process from product design to production management. For example, Jiangsu Jinwei Machinery Co., Ltd. uses three-dimensional modeling software for product design, uses finite element analysis software for structural optimization and strength analysis, uses computational fluid dynamics software for airflow field simulation and analysis, and uses CNC machining center for parts Processing, using computer-aided inspection system for product inspection, realizing the seamless connection between product design and production.

Intelligent. China's textile machinery manufacturing industry actively promotes the application of intelligent sensing, intelligent control, intelligent optimization and other technologies, realizing the comprehensive intelligence from product performance to production process. For example, Zhejiang Jinyi Technology Co., Ltd. has developed an online yarn quality monitoring system based on Internet of Things technology. By installing multiple sensors on the yarn production line, real-time data such as yarn diameter, elastic recovery rate, and breakage rate are collected. And through the cloud platform for data analysis and processing, real-time feedback to operators and managers, to achieve online monitoring and optimization of yarn quality.

Greening. China's textile machinery manufacturing industry actively promotes the application of electric, lightweight, oil-free and other technologies, realizing the comprehensive greening from product energy saving and emission reduction to production recycling. For example, Shandong Lutai Textile Co., Ltd. has developed a high-speed air-jet loom based on electric technology. By using an electric servo drive system instead of the traditional pneumatic drive system, the air-jet loom has achieved high-speed, low energy consumption, and low noise., Low-emission operation, saving a lot of energy and resources, and reducing the impact on the environment.

Analysis on Competition Pattern of 4. Textile Machinery Manufacturing Industry

(I) global textile machinery manufacturing industry competition pattern analysis

The global textile machinery manufacturing industry presents the following characteristics:

Industry concentration is high. The global textile machinery manufacturing industry is dominated by a few countries and regions, mainly concentrated in Europe, Asia Pacific and North America. Among them, Europe is the world's largest textile machinery manufacturing export region, accounting for about the share of global exports.50%It mainly relies on the technological advantages and brand influence of Germany, Italy, Switzerland and other countries to provide high-end, efficient and high-quality textile machinery products around the world. Asia Pacific is the world's largest textile machinery manufacturing market, accounting for about40%It mainly benefits from the rapid development of the textile and garment industry in China, India, Bangladesh and other countries and the large demand for textile machinery. North America is the innovation leading region of the global textile machinery manufacturing industry, mainly represented by the United States, and constantly introducing new technologies, new products and new models to provide new impetus for the development of the industry.

The product structure is more reasonable. The product structure of the global textile machinery manufacturing industry is more reasonable, which can meet the needs of different regions and different consumers. According to data from the Champ Consulting Group,2022In 2012, the product mix of the global textile machinery manufacturing industry consisted mainly of staple fiber processing equipment (accounting for approximately30%), long fiber processing equipment (accounting for about20%), knitting equipment (accounting for about15%), weaving equipment (accounting for about15%), dyeing and finishing equipment (accounting for about10%), other equipment (accounting for about10%). Among them, short fiber processing equipment and long fiber processing equipment are the leading products in the global textile machinery manufacturing industry, mainly used in the pretreatment and processing of raw materials such as cotton, felt, and chemical fibers. Knitting equipment and weaving equipment are important products in the global textile machinery manufacturing industry, mainly used in the production of knitwear and knitting. Dyeing and finishing equipment is an auxiliary product of the global textile machinery manufacturing industry, mainly used for dyeing, finishing, printing and other post-processing of textiles. Other equipment is the global textile machinery manufacturing industry complementary products, including non-woven equipment, textile testing equipment, textile accessories equipment.

The technical level is more advanced. The technical level of the global textile machinery manufacturing industry is relatively advanced, and new technologies, new products and new models are continuously introduced to provide new impetus for the development of the industry.2022The technological progress of the global textile machinery manufacturing industry is mainly reflected in the following aspects: digital, intelligent, green and service-oriented. Digitalization refers to the use of digital technology to optimize and integrate the design, production, management and service of textile machinery to realize the integration of information, networking, intelligence and service. Intelligence refers to the use of artificial intelligence, Internet of Things, big data, cloud computing and other technologies for intelligent perception, intelligent control, intelligent optimization and intelligent decision-making of textile machinery to achieve automation, intelligence and advanced forms of human-machine collaboration. Greening refers to the use of clean energy, new materials, new processes and other technologies to transform and innovate textile machinery in terms of energy saving, emission reduction, recycling, and waste treatment to achieve a low-carbon, environmentally friendly and sustainable development model. Servitization refers to the use of Internet, mobile communication and other technologies for remote monitoring, remote diagnosis, remote maintenance and other services of textile machinery to achieve efficient, convenient and satisfactory service experience.

Analysis on the Competition Pattern of Chinese Textile Machinery Manufacturing Industry in (II)

According to the data of Shangpu Consulting Group, China's textile machinery manufacturing industry presents the following characteristics:

The industry is large. China's textile machinery manufacturing industry is the world's largest textile machinery manufacturing market, accounting for about40%It mainly benefits from the rapid development of China's textile and garment industry and the large demand for textile machinery.2022Enterprises above the scale of China's textile machinery manufacturing industry reached about2000home, practitioners reached about6010,000 people, achieving a total industrial output value of about500It has provided a large number of high-quality products and services for domestic and foreign markets.

The product structure is more perfect. The product structure of China's textile machinery manufacturing industry is relatively perfect, which can meet the needs of different regions and different consumers.2022The product structure of China's textile machinery manufacturing industry mainly includes: short fiber processing equipment (accounting for about35%), long fiber processing equipment (accounting for about15%), knitting equipment (accounting for about20%), weaving equipment (accounting for about10%), dyeing and finishing equipment (accounting for about10%), other equipment (accounting for about10%). Among them, short fiber processing equipment and knitting equipment are the dominant products in China's textile machinery manufacturing industry, which are mainly used in the pretreatment and processing of raw materials such as cotton, felt, chemical fibers and the production of knitwear. Long fiber processing equipment and weaving equipment are inferior products in China's textile machinery manufacturing industry, which are mainly used in the pretreatment and processing of raw materials such as wool and silk, as well as the production of woven goods. Dyeing and finishing equipment and other equipment is China's textile machinery manufacturing industry auxiliary products, mainly used in the textile dyeing, finishing, printing and other post-processing and non-woven equipment, textile testing equipment, textile accessories equipment and other production.

The technical level is relatively improved. The technical level of China's textile machinery manufacturing industry has been improved, and new technologies, new products and new models have been continuously introduced to provide new impetus for the development of the industry.2022The technological progress of China's textile machinery manufacturing industry is mainly reflected in the following aspects: digital, intelligent, green and service-oriented. Digitalization refers to the use of digital technology to optimize and integrate the design, production, management and service of textile machinery to realize the integration of information, networking, intelligence and service. Intelligence refers to the use of artificial intelligence, Internet of Things, big data, cloud computing and other technologies for intelligent perception, intelligent control, intelligent optimization and intelligent decision-making of textile machinery to achieve automation, intelligence and advanced forms of human-machine collaboration. Greening refers to the use of clean energy, new materials, new processes and other technologies to transform and innovate textile machinery in terms of energy saving, emission reduction, recycling, and waste treatment to achieve a low-carbon, environmentally friendly and sustainable development model. Servitization refers to the use of Internet, mobile communication and other technologies for remote monitoring, remote diagnosis, remote maintenance and other services of textile machinery to achieve efficient, convenient and satisfactory service experience.

Development Trend and Challenge Analysis of 5. Textile Machinery Manufacturing Industry

(I) development trend analysis

According to the above analysis, it is expected that in the next few years, the global and China's textile machinery manufacturing industry will show the following development trends:

Market demand will maintain steady growth. With the global economic recovery and the effect of epidemic prevention and control, the global textile and apparel market demand will gradually recover and grow, thus driving the demand for textile machinery. At the same time, with the improvement of people's living standards and changes in consumption concepts, consumers' demand for textiles is becoming more and more diversified, personalized and high quality, which will also promote the upgrading of demand for textile machinery.

Technological innovation will become the core driving force for the development of the industry. With the continuous development and application of digital, intelligent, green and other technologies, the textile machinery manufacturing industry will usher in a new round of technological innovation and product upgrading, bringing new opportunities for the development of the industry. At the same time, with the upgrading of consumer demand and the improvement of environmental regulations, the textile machinery manufacturing industry will also face higher requirements and challenges, which will also promote technological innovation and product improvement in the industry.

Servitization will become an important direction for the development of the industry. With the popularization and development of Internet, mobile communication and other technologies, the textile machinery manufacturing industry will change from a simple product provider to a comprehensive service provider. By providing remote monitoring, remote diagnosis, remote maintenance and other services, it can achieve efficient, convenient and satisfactory service experience, enhance the interaction and trust with customers, and enhance customer loyalty and satisfaction.

Internationalization will become an inevitable choice for the development of the industry. With the acceleration of the process of globalization and the improvement of the trade environment, the textile machinery manufacturing industry will be more open and cooperative, through participation in international standard-setting, international exhibition exchanges, international market expansion and other ways to enhance their international influence and competitiveness, to achieve international development.

(II) Challenge Analysis

According to the above analysis, it is expected that in the next few years, the global and China's textile machinery manufacturing industry will face the following challenges:

Market competition will become more intense. With the recovery and growth of the global textile and apparel market demand, textile machinery manufacturers in various countries and regions will increase their competition and development of the market, resulting in more intense market competition. At the same time, with the rise of emerging markets and the application of new technologies, some emerging textile machinery manufacturing enterprises will challenge and impact the traditional textile machinery manufacturing enterprises, leading to changes in the market structure.

Technological innovation will be more difficult. With the upgrading of consumer demand and the improvement of environmental regulations, the textile machinery manufacturing industry will face higher requirements and challenges, which requires textile machinery manufacturing enterprises to continuously carry out technological innovation and product improvement to meet market demand and social development. However, technological innovation is a complex and difficult process, which requires a lot of capital investment, personnel training, intellectual property protection and other support conditions, which is a big problem for some small and medium-sized textile machinery manufacturing enterprises.

Servitization will be more complex. With the popularization and development of Internet, mobile communication and other technologies, consumers' expectations and requirements for service are getting higher and higher, which requires textile machinery manufacturing enterprises to provide more efficient, convenient and satisfactory service experience and enhance interaction and trust with customers. However, service is a multi-faceted, multi-level, multi-link complex process, the need to establish a sound service system, service standards, service channels and other support conditions, which for some traditional textile machinery manufacturing enterprises is not a small challenge.

Internationalization will be more difficult. With the acceleration of globalization and the improvement of the trade environment, textile machinery manufacturing enterprises will face a broader international market and more diverse international partners, which requires textile machinery manufacturing enterprises to adapt to different market needs, legal norms, cultural habits, etc., to enhance their international influence and competitiveness. However, internationalization is a complex process involving many aspects, multi-level and multi-link, which requires the establishment of a sound international strategy, international team, international network and other support conditions, which is not a small difficulty for some localized textile machinery manufacturing enterprises.

6. recommendations

According to the above analysis, in order to promote the high-quality development of China's textile machinery manufacturing industry, Shangpu Consulting believes that suggestions can be made from the following aspects:

Strengthen policy guidance and support. The government and industry associations should introduce more specific and effective policies, regulations and development plans to guide and support the transformation, upgrading and innovative development of the textile machinery manufacturing industry. For example, we can increase policy support for the textile machinery manufacturing industry in terms of financial subsidies, tax incentives and credit support to reduce the operating costs and risks of enterprises; we can increase policy support for technological research and development, personnel training and intellectual property protection in the textile machinery manufacturing industry to enhance the innovation ability and core competitiveness of enterprises; we can increase policy support for energy conservation and emission reduction, recycling, and waste disposal in the textile machinery manufacturing industry to promote the green development of enterprises and social responsibility.

Strengthen technological research and development and innovation. Textile machinery manufacturing enterprises should increase investment and efforts in technology research and development and innovation to meet market demand and social development. For example, we can strengthen cooperation with universities and scientific research institutions, introduce and train more talents with innovative spirit and practical ability, and establish a more perfect and efficient technology research and development system; we can strengthen the development and application of digital, intelligent and green technologies, and launch more high-end, efficient and high-quality textile machinery products; We can strengthen the research and analysis of market demand and consumer preferences, introduce more diversified, personalized and high quality textile machinery products.

Strengthen the service system and service quality. Textile machinery manufacturing enterprises should strengthen the construction and promotion of service system and service quality, so as to enhance the interaction and trust with customers. For example, we can strengthen the use of Internet, mobile communication and other technologies, establish more convenient and efficient service channels, and provide more timely and satisfactory service feedback; we can strengthen the use of remote monitoring, remote diagnosis, remote maintenance and other technologies to provide more professional and high-quality service guarantee; we can strengthen the tracking and evaluation of customer needs and satisfaction, Provide more personalized and customized service solutions.

Strengthen international strategy and international cooperation. Textile machinery manufacturing enterprises should strengthen the formulation and implementation of international strategies and international cooperation to enhance their international influence and competitiveness. For example, it can strengthen the research and analysis of the international market, formulate more reasonable and effective international market expansion strategies, and increase its own international market share; it can strengthen the participation and formulation of international standards, enhance its own voice in international standards, and enhance its own international brand image; it can strengthen exchanges and cooperation with international counterparts, and carry out more extensive and in-depth technical cooperation, product cooperation, project cooperation, etc, enhance their international innovation capabilities.

Concluding remarks

Textile machinery refers to the application in all aspects of the textile process, the natural fiber or chemical fiber processing into textiles required by the general term of all kinds of machinery and equipment. The textile machinery manufacturing industry is one of the traditional pillar industries in China. It has a complete industrial chain and rich product varieties, which provides strong equipment support for the domestic and foreign textile and garment markets. This paper analyzes the development environment, market scale, technological progress and competition pattern of textile machinery manufacturing industry at home and abroad.2023The development trend and challenges of textile machinery industry in, and put forward corresponding suggestions. I hope this article can help and inspire you.

Consulting Services

economic database

See more>Brand Rankings

See more>

Shangpu Consulting Group: Market Survey of Top Ten Brands of imported Fruits in January 2023

Shangpu Consulting Group: Market Research on Top Ten New Products of Electrical Appliances in December 2022

Shangpu Consulting Group: Market Survey of Top Ten Popular Brands in January 2023

Shangpu Consulting Group: Market Research on Top Ten Brands of Home Administration Cleaning in January 2023

Shangpu Consulting-Market Research & Consulting China Pioneer

immediate consultationOn July 05, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "In-process Plastic Market Research Project in the Automotive Sector. The customer said: The project report completed by Shangpu Consulting in cooperation with our company is due to the wide range of projects and strong professional products. Thank you very much for the professional and detailed market research report of Shangpu Consulting. I look forward to cooperating again next time and wish Shangpu Consulting by going up one storey! Once again, I would like to thank the users for their support and wish them a prosperous career and an evergreen foundation!

On July 05, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "Research Project of the Network Designated City Transport Company. The customer said: The market research project provided by Shangpu Consulting for our company has provided us with a valuable reference basis for objectively evaluating the current market situation of the industry and achieved the expected goal. I also wish Champ Consulting the development of by going up one storey! Once again, I would like to thank the users for their support and wish them a prosperous career and an evergreen foundation!

July 07, 2020, Shangpu Consulting received a satisfaction evaluation sheet from the customer's "Lithium Battery Enterprise Sales Strategy and Production Cost Research Project. The customer said: The market research project provided by Shangpu Consulting for our company has provided us with a valuable reference basis for objectively evaluating the current market situation of the industry and achieved the expected goal. I also wish Champ Consulting the development of by going up one storey! Once again, I would like to thank the users for their support and wish them a prosperous career and an evergreen foundation!

On July 09, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for a hazardous waste treatment research project. The customer said: this is the organizational structure of the survey, the service process is very good, wish your company's consulting work is getting better and better, look forward to the next cooperation. I wish users a prosperous career, evergreen foundation!

On July 16, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the Shared Beauty Research Project. The customer said: The content of Phase I and Phase II is satisfactory, and we look forward to signing a long-term agreement in the later period. The research part of the country will continue to cooperate with your company. I wish users a prosperous career, evergreen foundation!

On July 09, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "Research Project on the Organizational Structure of Two Liquor Production Enterprises. The customer said: This is an organizational structure survey, the service process is very good, looking forward to the next cooperation. I wish users a prosperous career, evergreen foundation!

On July 13, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "Research Project on the Operation of a Brand. The customer said: The content of Phase I and Phase II is satisfactory, and we look forward to signing a long-term agreement in the later period. The research part of the country will continue to cooperate with your company. I wish users a prosperous career, evergreen foundation!

On July 13, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "Zhoushan Sand and Stone Aggregate Market Research Project. The customer said: I am very satisfied with the consulting service provided by Shangpu Consulting. Shangpu Consulting can think of the customer, solve the problem for the customer in time, and do not hesitate to work overtime to meet the customer's needs. Our company is very grateful for this. I wish users a prosperous career, evergreen foundation!

On July 15, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "Brand Building and Protection Solutions Enterprise Research Project. The customer said: overall very satisfied, timely feedback, smooth communication, hope to cooperate more. I wish users a prosperous career, evergreen foundation!

On July 16, 2021, Shangpu Consulting received a satisfaction evaluation sheet from the customer for the "Research Project on the Rental Market of Mounter. The customer said: I am very satisfied with the consulting service provided by Shangpu Consulting. Shangpu Consulting can think of the customer, solve the problem for the customer in time, and do not hesitate to work overtime to meet the customer's needs. Our company is very grateful for this. I wish users a prosperous career, evergreen foundation!

| Research Module | research content | ||||||

|---|---|---|---|---|---|---|---|

| Market research | Industry status | market capacity | Product Application | channel mode | Supply chain | market competition | Market Consulting |

| Competitor Research | Enterprise background | Enterprise Finance | Sales Data | Market Strategy | Production Equipment | Supply Procurement | Technology R & D |

| warehousing logistics | channel construction | Human Resources | Enterprise Strategy | ||||

| User Research | Consumer Survey | consumption behavior attitude | Publicity/Promotion | Product Service | Brand Research | consumer characteristics | |

| satisfaction survey | Employee satisfaction | user satisfaction | |||||

| Market Entry Advisory | Macro Industry Research | competitive enterprise research | Downstream User Research | Channel Research | Due Diligence | Return on Investment | |

| Floor module | Landing implementation recommendations | Long-term cooperation | |||||

| Business investment due diligence | Target industry market investment value due diligence | Industry Benchmarking Enterprise Research | Target Enterprise Credit Assessment Report | Project investment due diligence | |||

| industry planning | Market research | market access | development strategy | investment location | Acquisition and integration | IPO Fundraising | |

| Credit Report | Basic information | Major Events | Production/Operation Network | enterprise scale | Operating strength | Financial strength | Legal risk |

| Future business prediction | Overall credit rating | cooperative risk warning | |||||

| Brand/Sales Proof | Market Share Proof | Market Share Proof | Proof of brand strength | Industry Proof | Specialized new proof | Proof of sales strength | Proof of technological leadership |

| National/Global Status Certificate | |||||||

15 Year

15 years of Shangpu consulting

48 Intellectual Property Rights

Independent methodology

80% of the information comes from first-hand research.

118 Billionth

Self-built database 11.8 billion

Covering 1978 industries in China

0.1 billion new data per year

Industry Big Data Platform

118 +

Have a 300 team of professional consultants

Practical operation and management experience of top enterprises

88% of members have international PMP certificates

48 Item

Independent methodology

48 independent intellectual property rights

high-tech enterprise

Industry Big Data Platform

400-969-2866